Gauging

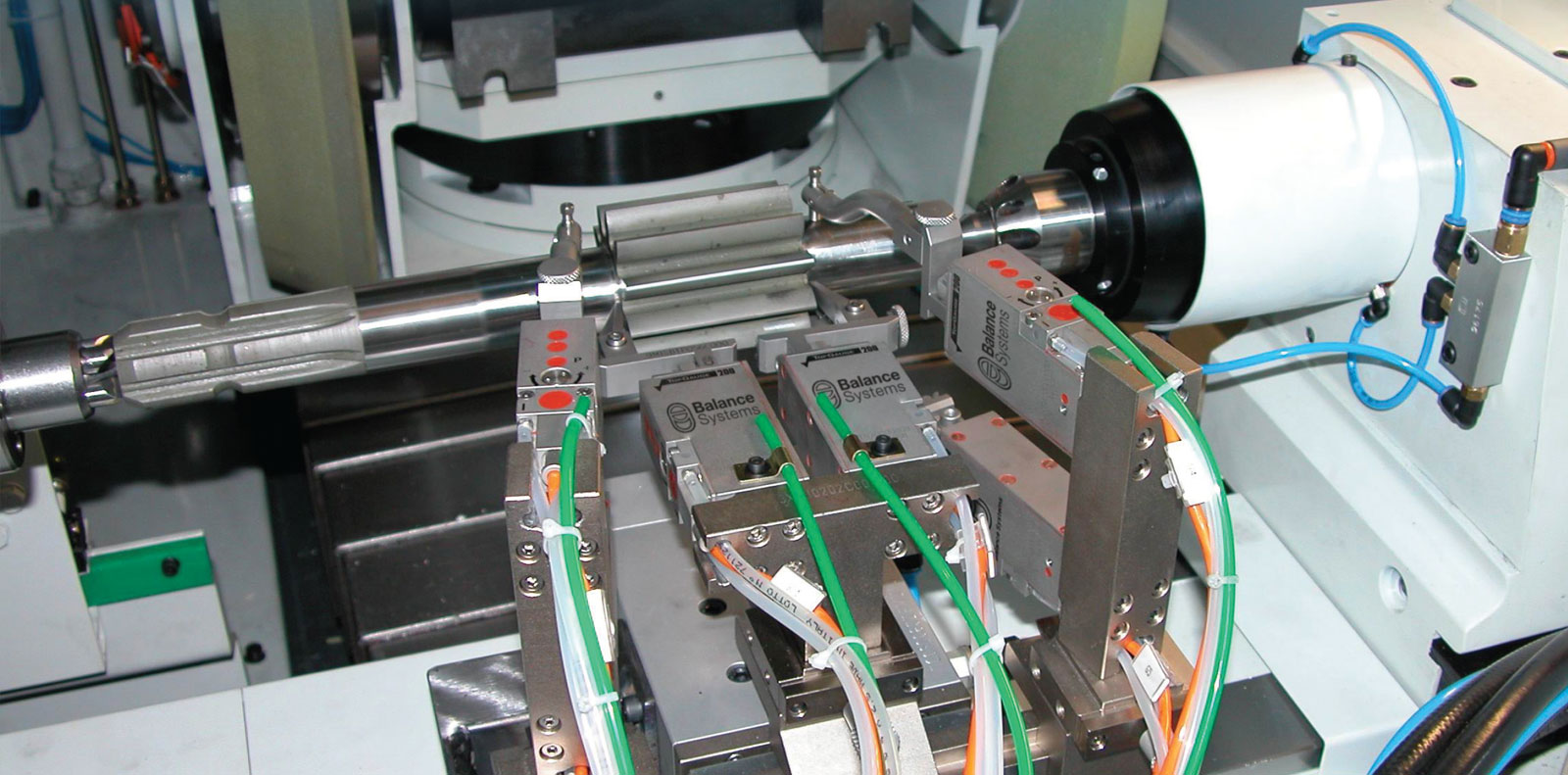

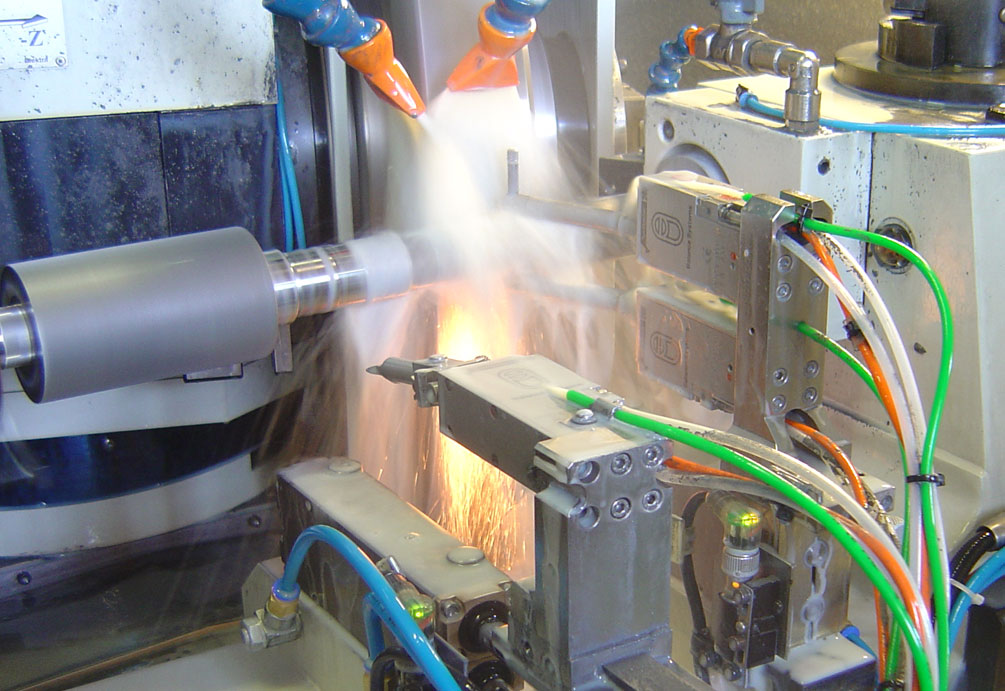

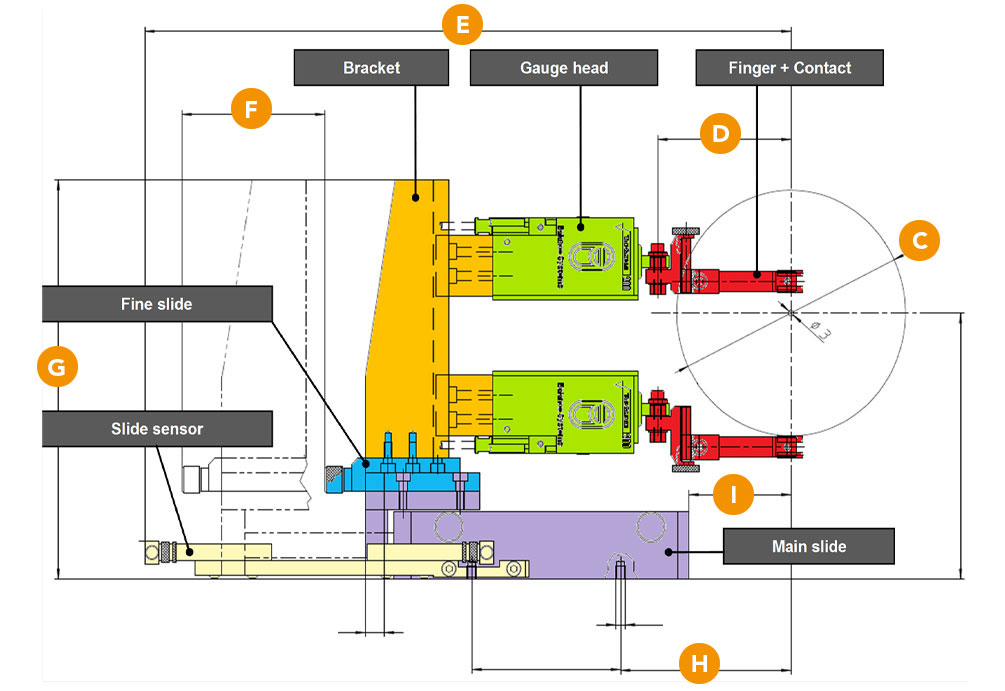

In high-volume production contexts, cycle-times and quality-steadiness matter. The in-process gauging system helps to save a lot of time per workpiece through the detection of the actual dimension of the part being grinded. This variable value, typically diameters, is used to automatically control the material removal based on the desired final dimension.

This presents a critical step towards the full optimization of grinding operations in a computer numerically controlled (CNC) environment.