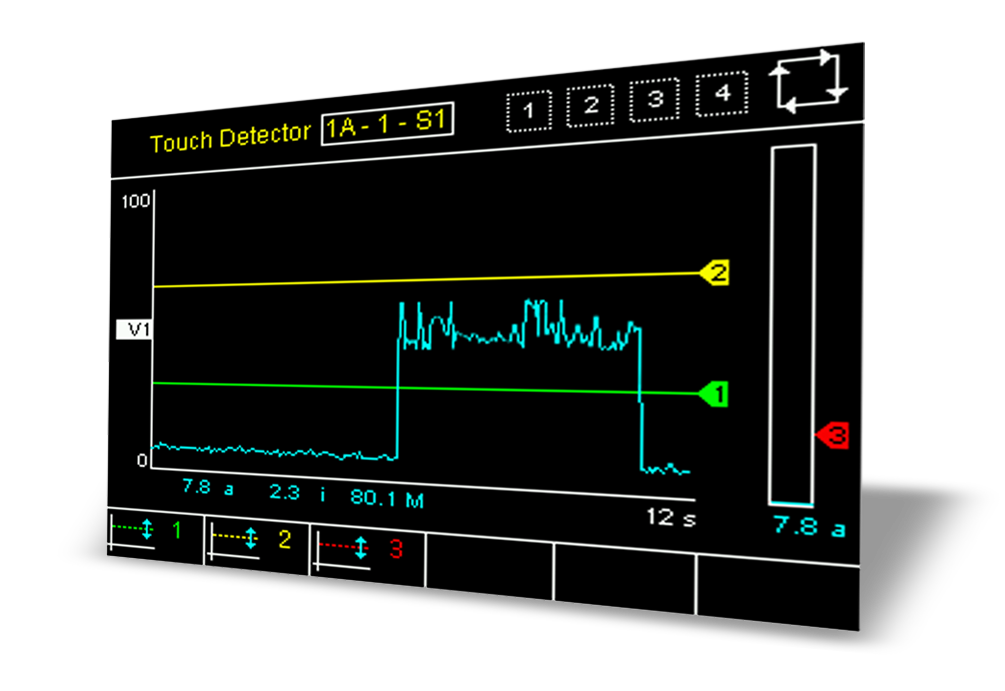

Touch Detection

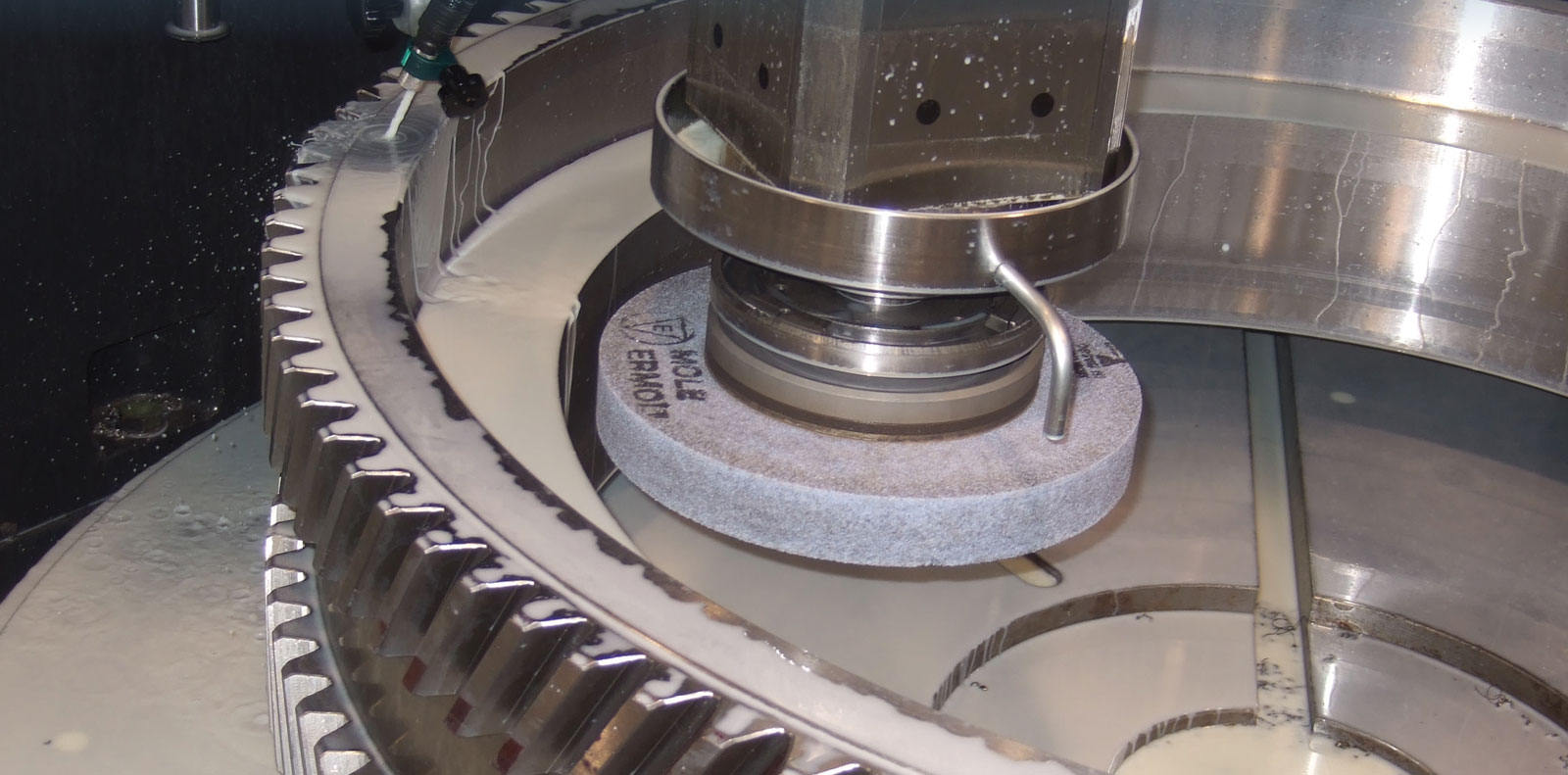

Touch Detection (TD) system is critical for an efficient grinding process. Essentially, this feature detects the exact moment when the grinding wheel touches the workpiece or the dresser, and this results in the identification and classification of the contact events automatically from the measured data. These parameters include grinding power and Acoustic Emission (AE).

A TD system affects positively on different grinding stages including:

1) the elimination of the gap between the wheel and workpiece, 2) during the approach of the wheel to the workpiece, 3) during the wheel dressings, and 4) during any machine crashes.