Your safety solution

-

Multifunctionality

-

Predictive maintenance at your service

-

Suitable for each application

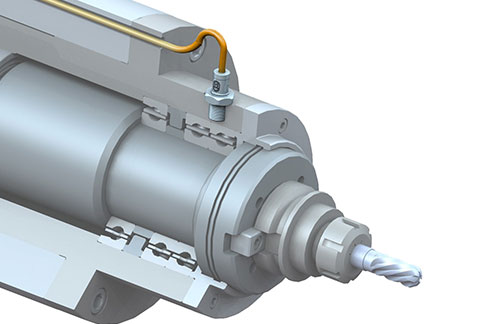

B-Safe X System was invented to expand spindles and machine tools diagnostics according to vibration and temperature analysis. The miniaturised system can be installed directly on your spindle guaranteeing a real-time monitoring, as well as reducing the machine downtimes by predicting malfunctions.

Crash protection

Instant stop of the machine

Continuous monitoring

Continues to record data

when the machine is off

Black box

Embedded data logger

Industry 4.0 upgrade

Information sharing

Innovative solution

The hybrid technology MEMS 3D and piezoelectric guarantees a complete signals analysis on a wide band. The presence of a microprocessor with integrated memory allows local detection and memorization of collision phenomena, unbalances, overloads, anomalies of the working cycle, tools wear and bearings diagnostics.

Predictive maintenance at your service

B-Safe X Spindle Check-Up function includes a series of algorithms to check the efficiency level of your productive process, with the aim of maximizing the productivity of your machines and the quality of your products. The statistical analysis provided by the system gives an essential support for planning maintenance interventions, according to the real use of your equipment

EVOLVE your factory

B-Safe Cloud is the online evolution of B-Safe System, which allows you to remotely supervise all the sensors installed on your machine tools and monitoring their productivity status. Through the B-Messanger tool, you can personalise the alerts that can be received via SMS, e-mail, or push notification of smartphones. Moreover, it is possible to access to the wide range of B-Safe features through the dedicated web portal or with the B-Safe Cloud APP (both iOS and Android devices).

Today you can start the path for a safer company

B-Safe X is a set of different evolved technologies, which allows you to create a distributed and interconnected system of analysis and supervision of your production plant.

Come and meet

our B-Safe X System

Ask for a free ticket for fair events where you want to test our system for spindles and machine tools.

List of Exhibitions 2020