Recent products

Discover products specifically designed to meet your needs.

Innovative solutions since 1975

Design & Development 100% made in Italy

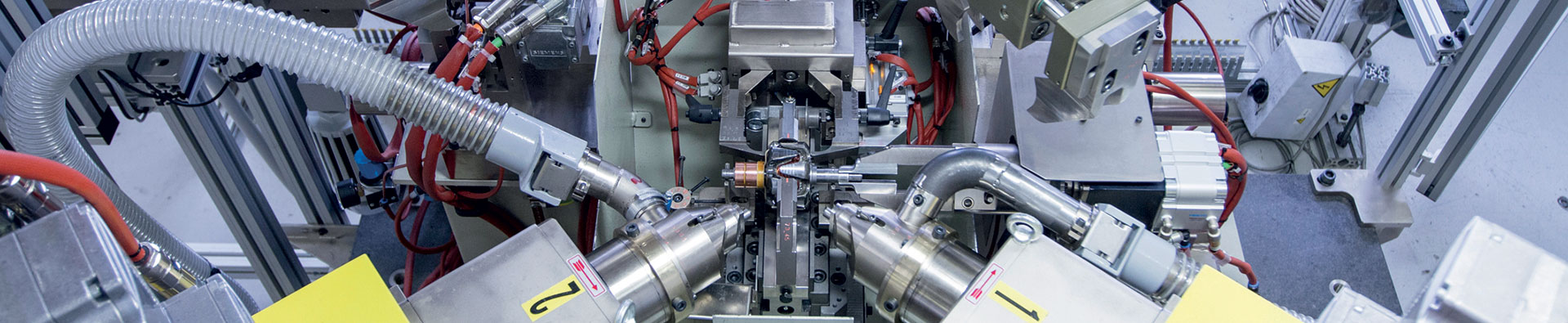

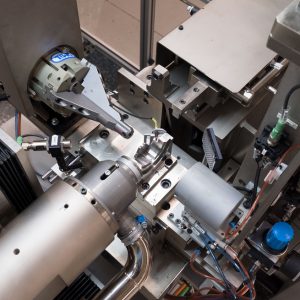

At Balance Systems we create technologically advanced products for two core businesses: Manual, semi-automatic and automatic customized balancing machines for a wide range of sectors and Process control systems with specific functions suitable to grinding machines: automatic grinding wheel balancing (1 and 2 planes), touch detection (gap & crash), comparative and absolute in-process gauging.

NEWS & EVENTS

Keep updated with all products, events, and exhibitions news

about our entire network

-

Balance Systems takes center stage at InnoMec+: innovation and sustainability for the mechanics of the futureLombardy confirms its position as the beating heart of Italian industrial innovation. Balance Systems is the key player in InnoMec+, the research and development project that won the “Collabora & Innova” tender promoted by the Lombardy Region as part of the 2021-2027 ERDF Program. InnoMec+ was created with the aim of guiding the transition towards more sustainable, digital, and secure manufacturing, capable of responding to the challenges of electric mobility and Industry 4.0. The project involves companies and research centers that will work together to create an innovative framework capable of optimizing production processes, reducing energy consumption, valorizing production waste, and ensuring the security of industrial data through advanced digital technologies and blockchain.Read more

The role of Balance Systems

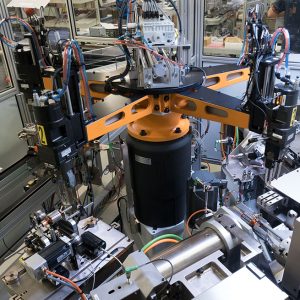

Balance Systems participates as an industrial end-user, making a crucial contribution to the development and validation of new technologies applied to green mobility. In particular, the company will be involved in:- Designing and building a new modular and scalable balancing machine, designed for electric motor components.

- Field validation of the hardware/software framework that will enable real-time monitoring of consumption, processes, and production waste, making production more efficient and sustainable.

- Application of data-driven and cybersecurity solutions to ensure maximum security and traceability of industrial data.

Innovation, sustainability, and competitiveness

Thanks to InnoMec+, Balance Systems is strengthening its commitment to manufacturing that combines technological innovation and environmental responsibility, elements that are now essential for competing in international markets. The project also represents a strategic opportunity for the entire Lombardy metalworking industry, which is called upon to renew itself in order to remain competitive globally and face the challenges of ecological and digital transition. -

Summer Break 2025Read moreWe would like to inform you that our offices will be closed for summer holidays from the 4th to the 22nd of August, included.Working activity will resume regularly on Monday 25th of August.For technical support, please call +39 02 9504955 or send an email to:PROCESS CONTROL SYSTEMS - Closing from August 8th to August 18th systems.service@balancesystems.itBALANCING MACHINES - Closing on August 15thDuring the closing period, the Service Dept. will be available for remote support and delivery of emergency spare parts only (machines stopped).Our service is available from Monday to Friday, from 8:30 to 12:30 and from 13:30 to 17:00 GMT+1.Balance Systems Staff

- Read more

Summer Break 2025

We would like to inform you that our offices will be closed for summer holidays from the 4th to the 22nd of August, included.Working activity will resume regularly on Monday 25th of August.For technical support, please call +39 02 9504955 or send an email to:PROCESS CONTROL SYSTEMS - Closing from August 8th to August 18th systems.service@balancesystems.itBALANCING MACHINES - Closing on August 15thDuring the closing period, the Service Dept. will be available for remote support and delivery of emergency spare parts only (machines stopped).Our service is available from Monday to Friday, from 8:30 to 12:30 and from 13:30 to 17:00 GMT+1.Balance Systems StaffRead moreEMO 2025 | Hall 11 Booth G64

We’re excited to announce our participation in EMO 2025, the world’s leading trade fair for production technology, that will take place from the 22nd to the 26th of September, 2025. At our booth, we’ll showcase our latest innovations in Process Control Systems for CNC machine tools and grinding machines. Come and discover the new GT-S product range, designed to optimize machining performance, improve process reliability, and ensure maximum precision across all grinding applications. You’ll also find our well-established VM25, featuring: • Absolute Balancer • Tekor Measurement System • AE and Power Sensors • TGA200 • Ring Balancer In addition, a dedicated area will highlight our advanced Smart Sensors technology, including B-Safe, Sequoia, and upcoming innovations designed to expand diagnostic capabilities and predictive maintenance in modern production environments. Visit us at our stand and discover how we can support your machining processes. Contact us now to receive your free entry pass!

DATES: from the 22nd to the 26th of September, 2025 | Hannover, Germany PASS: Get your free ticket INFO: EMO websiteRead moreCOILTECH USA 2025 | Booth N06

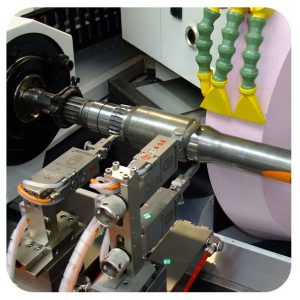

From the 11th to the 12th of June, 2025 we will exhibit at Coiltech in Novi, USA. At our stand you can ask for information to our experts about our balancing machines, advanced technological solutions that allow to delete the rotating parts vibration of electrical, mechanical and electromechanical machines, improving their life and performances. Our balancing machines typologies are:

- Automatic and semi-automatic balancing machines for armatures and rotors. Unbalance correction by drilling or milling.

- Automatic and semi-automatic balancing machines for fans and electric fans. Unbalance correction by weights addition or material removal.

- Horizontal manual balancing machines for shafts and rotors. Unbalance correction by masses addition and displacement, milling and drilling.

- Manual, semi-automatic and automatic balancing machines for disk-shaped rotating components. Correction of the unbalance by drilling or milling.

- Manual and semi-automatic balancing machines for turbochargers. Correction of the unbalance by milling or grinding.

- A production offer of vertical and horizontal balancing machines;

- Retrofit of old own machines or of any other manufacturer;

- A department entirely dedicated to contract balancing, with more than 12 balancing machines of own production.

DATES: 11th - 12th of June, 2025 | Novi, USA EXHIBITORS: Balance Systems and EBS INFO: Coiltech website