Mass unbalance is the most common malfunction of rotating machinery. It produces excessive synchronous forces that cause vibrations and mechanical failures, along with increasing the noise level and energy consumption.

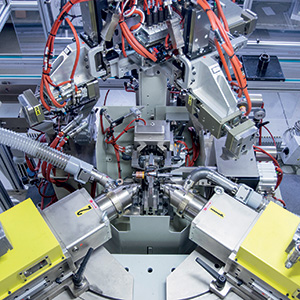

In order to correct the aforementioned problems, each rotating body needs to be balanced during the production process by means of a balancing machine.

Designing and producing balancing machines has always been our business.

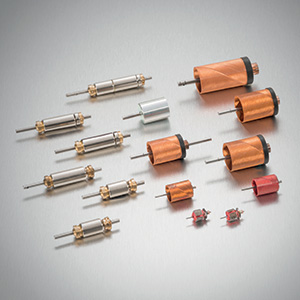

We are specialized in the development of high precision, high production and completely flexible machines.

In addition, our R&D department is always available to our customers to develop customized products according to their specific requirements.