Product Description

| Technical data | |

|---|---|

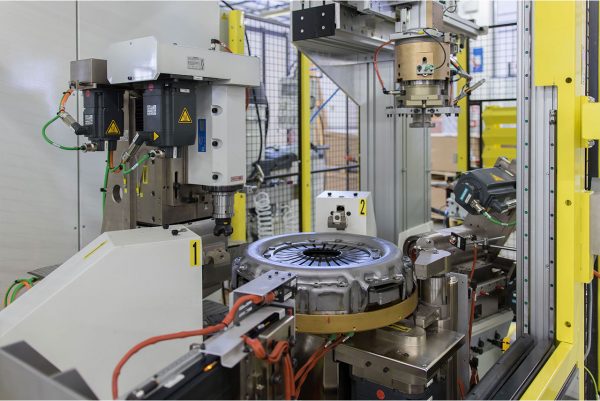

| Max rotor external diameter: | 500 mm (19.68 in) |

| Max rotor internal diameter: | 260 mm (10.24 in) |

| Max rotor height: | 80 mm (3.15 in) |

| Max rotor weight: | 60 kg (132.28 lb) |

| Cycle time: | < 100 s |

| Balancing method: | Axial milling and/or radial drilling |

| Balancing speed: | 500-700 rpm |

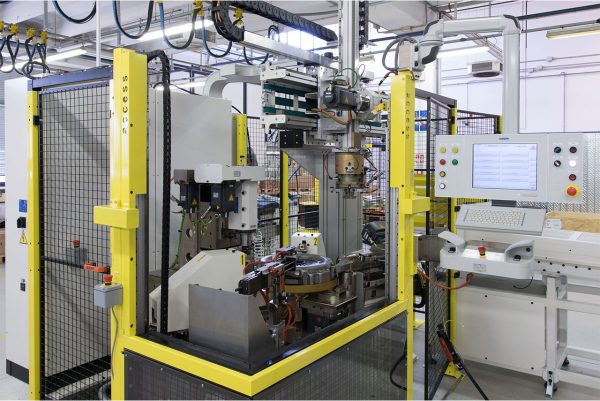

| Controlled by: | Industrial PC |

| Power: | 7 kVa |

| Power supply: | 400-480V+PE three-phase 50/60 Hz |

| Machine weight: | 3200 kg (7054.79 lb) |

| Machine dimensions (LxWxH): | 3500 x 3500 x 3320 mm (137.79 x 137.79 x 130.71 in) |

| Options |

|---|

| Tele-service |

| Industrial vacuum cleaner |

| SPC / SW |

| Master Rotor |

| Marking device |

| Radial drilling unit |