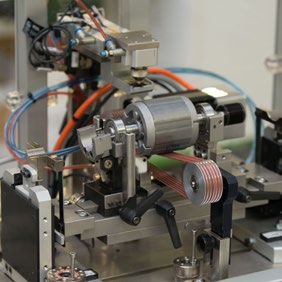

Product Description

| Technical data | |

|---|---|

| Max rotor weight | 4 kg (8,82 lb) |

| Rotor diameter: | 20-80 mm (0,79-3,15 in) |

| Stack lamination height: | 20-80 mm (0,79-3,15 in) |

| Max production rate: | 140-180 pcs./hour |

| Controlled by: | Industrial PC |

| Measuring precision: | 0.1 gmm/kg max (0,04 oz.in/lb) |

| Balancing method: | Radial drilling or axial milling |

| Power supply: | 380-480 V three-phase 50/60 Hz |

| Machine dimensions (LxWxH): | 1500 x 1700 x 2200 mm (59,06 x 66,93 x 86,61 in) |

| Options |

|---|

| Re-checking unit |

| Industrial Vacuum cleaner for drilling chips |

| SPC/SW and printer |

| Printer |

| Teleservice |

| Marking device |