Product Description

| Technical data | |

|---|---|

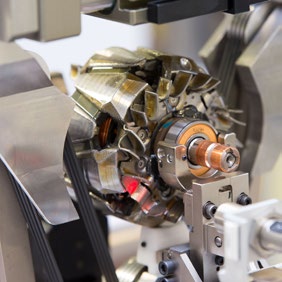

| Max rotor weight: | 4 kg (8,82 lb) |

| Rotor diameter: | 50-120 mm (1,97-4,72 in) |

| Stack lamination height: | 20-100 mm (0,79-3,94 in) |

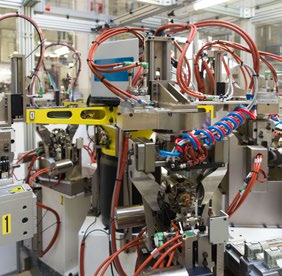

| Max production rate: | 360 pcs./hour |

| Controlled by: | Industrial PC |

| Measuring precision: | 0.1 gmm/kg max (0,04 oz.in/lb) |

| Balancing method: | Inclined drilling |

| Power supply: | 380-480 V three-phase 50/50 Hz |

| Machine dimensions (LxWxH): | 3400 x 3600 x 2450 mm (133,86 x 141,73 x 96,46 in) |

| Options |

|---|

| Reject conveyor |

| Industrial Vacuum cleaner for removing of drilling chips |

| SPC/SW |

| Printer |

| Teleservice |

| Device for balancing rotors with ball bearings assembled |