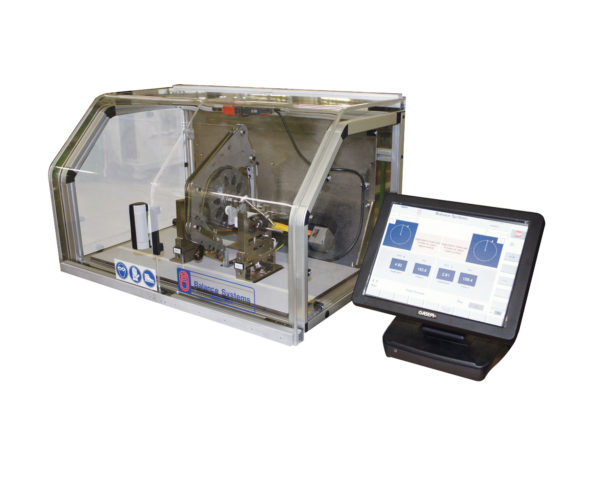

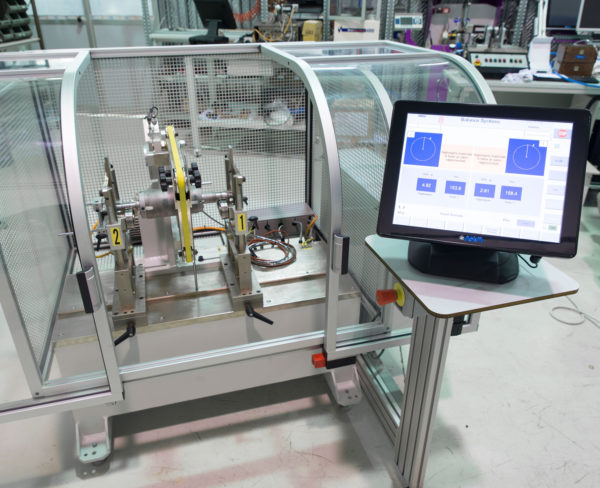

Product Description

| Technical data | |

|---|---|

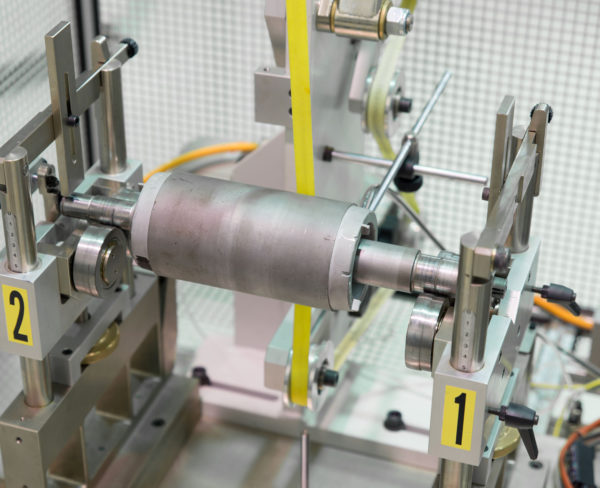

| Max rotor weight | 25 kg (55.11 lb) |

| Rotors diameter | 30-170mm (1.18-6.69 in) |

| Stack lamination height | 40-200mm (1.57-7.87 in) |

| Unbalance measuring time: | 8-20 s |

| Controlled by | Industrial PC |

| Drive systems: | Tangential or loop belt |

| Balancing method | Material adding or removal |

| Measuring precision: | 0.5 gmm/kg max |

| Power supply | 110-230V 50/60Hz |

| Machine dimensions (LxWxH) |

840 x 680 x 580 mm (33.07 x 26.77 x 22.83 in)

|

| Options |

|---|

| Master rotor |

| Tele-service |

|

Table

|

| Digital display |

|

Printer

|