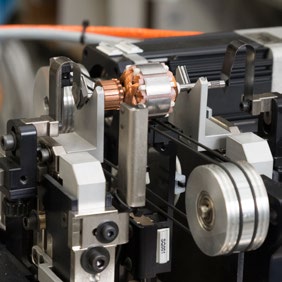

Product Description

| Technical data | |

|---|---|

| Parts max weight: | 3 kg (6,61 lb) |

| Parts diameters min/max: | 15-90 mm (0,59-3,54 in) |

| Stack lamination height min/max: | 20-80 mm (0,79-3,15 in) |

| Unbalance measuring time: | 7 s |

| Controlled by: | Industrial PC |

| Measuring accuracy: | 0.1 gmm/kg max (0,04 oz.in/lb) |

| Power supply: | 110-240 V 50/60 Hz |

| Power requirement: | 0.3 kW |

| Options |

|---|

| Table |

| Tele-Service |

| Printer |

| Indipendent manual correction unit by drilling |