Product Description

Requirements

High speed cutting machining centers allow the increase of productivity with a better quality of the final product.

In order to ensure this quality over time, and to avoid all costs connected with machine “down time”, re-working, rejects, early substitutions of tools and machine components, the vibrations due to the unbalance of the combination tool-toolholder-spindle, must systematically be measured with a reference to a control plane.

According to specific cases, the unbalance can be corrected on site, bringing it back within its best limits, or eliminated by a forthcoming more radical, planned maintenance activity.

Solution

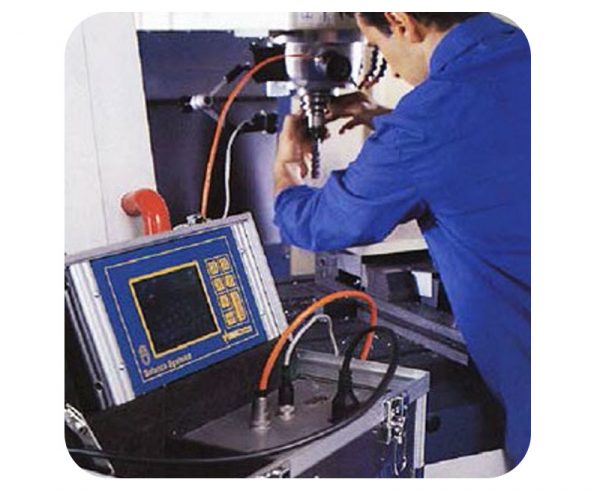

In order to satisfy measuring and unbalance correction needs, Balance Systems introduces its device BEST BALANCE 1000.

Best Balance 1000 is a workshop portable, easy to use and extremely adaptable device.

It is designed for tools and machine tools but is also used to measure and correct the unbalance of other rotating components, which are present in the workshop, such grinding wheels, pulleys, rotors, fans, etc.

Functioning

The operator can choose the unbalance measurement unit and among five different languages with which the system will completely guide him in the correction procedure.

The device prompts by a graphic interface:

- Magnitude and position of the detected unbalance

- Rotational speed of the component which has to be corrected

- Amount and position of the corrections

Several correction methods are available:

- Displacement of correction weights which can be already fitted or further added

- Positioning of eccentric rings already fitted on the rotating body

- Addition of weights in pre-defined positions

Configuration

- Anti-scratch case with handle, shoulder strap and double lock

- Control panel with a multi-function keyboard and a graphic display

- Rack with power supply unit and measuring board

- Vibrations transducer

- Photoelectric sensor to detect the rotational speed

- Magnetic fitting bracket for sensors

- Refracting adhesive

- Power cord