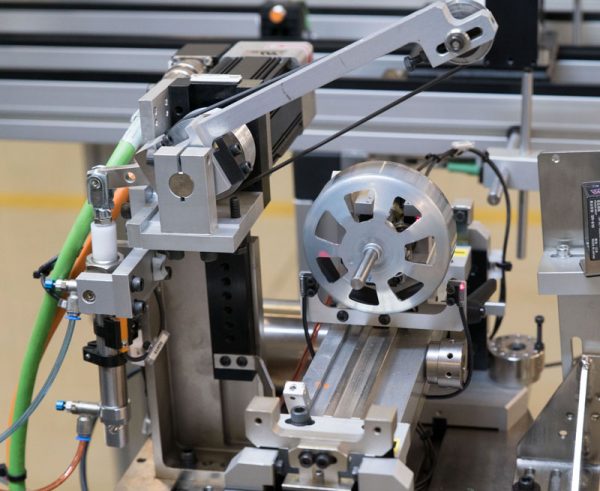

Product Description

| Technical data | |

|---|---|

| Max disc diameter: | 90 mm (3.54 in) |

| Max disc height: | 35 mm (1.38 in) |

| Max disc weight: | 340 g (0.75 lb) |

| Max machine cycle time: | 26 s |

| Balancing method: | External radial milling |

| Balancing speed: | Programmable |

| Max sensibility: | 0,5 gmm/kg |

| Productivity: | Cmk >= 1,33 |

| Controlled by: | Industrial PC |

| Power: | 6 kVa |

| Power supply: | 400 V / 50 Hz / 25 A |

| Machine weight: | 2500 kg (5511.56 lb) |

| Machine dimensions: | 2300x4118x2600 mm (90.55×162.13×102.36 in) |

| Options |

|---|

| Tele-service |

| Printer |

| Industrial vacuum cleaner |

| SPC / SW |

| Out of tolerance pieces storage |

| Master Certificate |

| Bar-code/data matrix reader |

| Safety protection |